ADVANCED MAGNETIC LOSS TESTING

>accuracy through physical consistency<

<< A >> The Challenge

World-wide, reduced energy consumption of electric machines and apparatuses, has become priority, supported by regulations and standards for improved industrial production.

In particular, this concerns electric machines like transformers, generators and motors. They contain cores of soft magnetic silicon iron. It is outmost importance to be able to characterize these materials in exact ways.

However, the so far applied standard test systems yield test results where the absolute accuracy is questionable. The reason is that they are based on a physically not consistent principle that is applied since more than 100 years without significant improvement. Thus, the test results are restricted to approximate comparisons.

The actual challenge results from the increased relevance of modern machines that are not operated with 50 Hz or 60 Hz, but with so-called medium (or „high“) frequency, up to several kHz. For example, this is valid for electro-mobility and for energy conversion that is supported by advanced electronics. In general, urgent demand is given for effective measurement systems of predictable absolute accuracy.

<< B >> Today’s Situation

At present, two internationally IEC-standardized test systems are available for so-called „technical“ frequencies of 50 Hz, or 60 Hz, respectively:

(i) The Single Sheet Tester (SST; IEC 60404-3) for steel samples of 50 cm x 50 cm size –

The SST is characterized by high reproducibility. On the other hand, the absolute accuracy is not known, due to the fact that the losses are derived in indirect ways from the over-all power consumption of the sum of sample and magnetization yoke system. Further disadvantages are the considerably large size of test apparatus, its extremely high mass and the resulting high costs of system.

(ii) The Epstein Frame (IEC 60404-2) for about two dozens of sample strips of 28 cm x 3 cm size –

Also here, losses are derived in indirect Watt-metric ways from the total power consumption of the inhomogeneous magnetic frame. Further disadvantages are time consuming sample preparation and handling, as well as errors from slitting and annealing.

<< C >> The Concept of ViennaMagnetics

ViennaMagnetics offers completely novel solutions that allow for direct, accurate, rapid and cost-effective measurements of losses over a large frequency range.

The VM Precision Lossmeter offers tests up to 1 kHz (with possible extension, up to 10 kHz). As an option, the course of time of induction can be synthesized, e.g. through 5000 points for 50 Hz.

Absolute accuracy values of estimated 2% result from a concentration on the homogneously magnetized sample region. It shows a 1D Maxwell/Poynting-Field, as a pre-condition for a physically correct, consistent direct determination of losses. The disadvantages of the Watt-metric power measurement at the inhomogeneous magnetic circle is thus avoided. The applied HF magnetization yoke has no direct impact on the results of measurement.

The test procedure comprises three physically consistent steps:

(1) precise approximation of induction, with true-field air flux compensation,

(2) optimized detection of induction and field (by means of a „Giant Tangential H-coil“),

(3) precise evaluation of instantaneous power p and of time-averaged losses P.

<< D >> Advantages of VM Precision Lossmeter versus SST:

- extreme reduction of mass (ca. 60 kg) by means of a small high frequency yoke

- reduced size of – desktop-compatible – apparatus to 80 cm x 55 cm x 19 cm, by means of reduced sample width to 17 cm, as being sufficient for the homogeneous structure of modern steel types; sample length of 50 cm unchanged, corresponding to IEC Standards 60404-3

- enlarged range of frequency: 50 Hz to 500 Hz for Series Basic, 162/3 Hz to 1 kHz for Series Enhanced; 50 Hz results close to Standard-SST

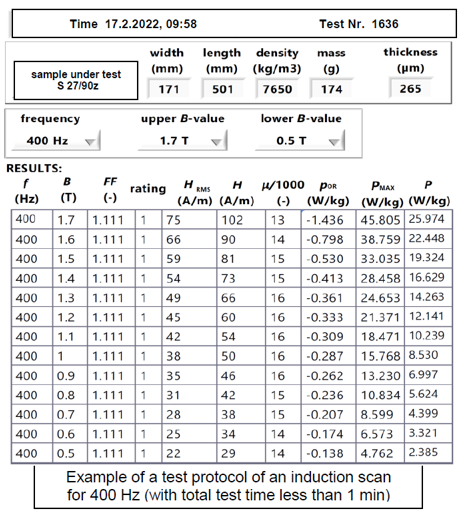

- simplified, extremely rapid test procedures (ca. 10 measurements per minute)

- automatic scan over induction (over frequency as an option)

- instantaneous output of results by integrated laptop PC, as well as by A4 protocol printer

(extra data processing possible via text files)

<< E >> Video PLM

<< F >> Options

Please ask for options like the following:

- other sample format (larger / smaller)

- further increase of frequency (kHz region)

- frequency scan

- demagnetization program

- distortion test scan

- programmable magnetization wave-form*

- temperature variation tests*

- university apparatus*

- research cooperation*

*) ask for university discount

<< G >> Summary

ViennaMagnetics Lossmeters are compact, simple and rapidly useable desktop apparatuses, for physically correct measurements of magnetic losses of electric steel, for frequencies up to Kilo Hertz, at a compact format of sample sheet.

<< H >> ViennaMagnetics

VM is a high-tech start-up of Vienna University of Technology (TU Wien). VM takes advantage of 40 years of scientific research, documented by more than 250 publications in the field of Technical Magnetism. VM is a technology leader in magnetic loss measurements, and thus offering itself as a natural partner in this area.

Registered business areas of ViennaMagnetics GmbH are magnetic measurement systems (for losses, magnetostriction, rotational magnetization etc.), experimental and numerical analyses, as well as sensors (for magnetism, and for physiology; in particular thin band sensors).

<< I >> Team

Scientific Director Prof.Dr. Helmut PFÜTZNER

Technical Director Dr.Georgi SHILYASHKI

Business Development Manager Dr.Claes BENGTSSON

Chemical Expert Lena MELZER M.Sc.

Legal Expert Blagovesta NIKOLOVA LL.M.

<< J >> Contact:

email: office@viennamagnetics.eu

phone: +43 664 3989299

ViennaMagnetics GmbH, Tabor Strasse 11, 1020 Wien, Austria;

VM Show Room, Leopoldsgasse 25 / Schwarzingergasse 2, 1020 Wien, Austria

<< K >> Examples of Corresponding Publications

G.Shilyashki, H.Pfützner, C.Bengtsson, E.Huber, “Time-averaged and instantaneous magnetic loss characteristics of different products of electrical steel for frequencies of 162/3 Hz up to 500 Hz,” IET El.Pow.Appl. (2022).

H.Pfützner, G.Shilyashki, “Theoretical basis for physically correct measurement and interpretation of magnetic energy losses,” IEEE Trans.Magn. 54, 630020 (2018).

H.Pfützner, G.Shilyashki: “Concept for industrially relevant magnetic power loss measurements by Single Sheet Tester and Epstein Frame Testers,” CIGRE Science & Engineering 9, 95-109 (2017).

H.Pfützner, G.Shilyashki, M.Palkovits, V.Galabov: “Concept for more correct iron losses measurements considering path length dynamics,” Int.J.Appl. Electrom. Mech. 44, 259-270 (2014).

H.Pfützner: “On the determination of magnetic losses from the field quantities (in German),” Arch.El.Techn. 60, 177-179 (1978).